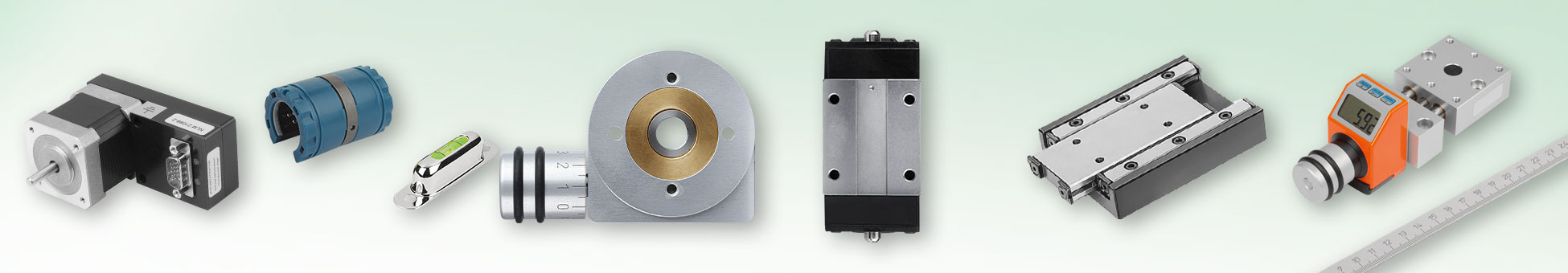

Smart products from norelem

The optimum solution for smooth production!

New products. New possibilities.

Our unique selection is now even bigger.

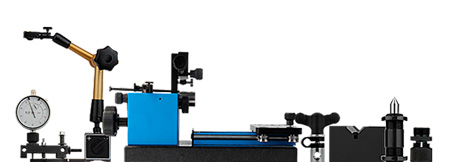

Linear systems, guide elements,

positioning units

Locating pins

stable and precise connection

norelem positions

Handwheels

norelem positions

Ball lock pins

norelem moves

Couplings

norelem positions

Spring plungers

norelem positions

Indexing plungers

Choose from our product groups

The most important norelem benefits - you can rely on them

How can we help you?

Whether it's about orders, product information or technical details,

our experts will enthusiastically help you with your project: